engine oil Ram 1500 2013 Get to Know Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2013, Model line: 1500, Model: Ram 1500 2013Pages: 196, PDF Size: 9.66 MB

Page 10 of 196

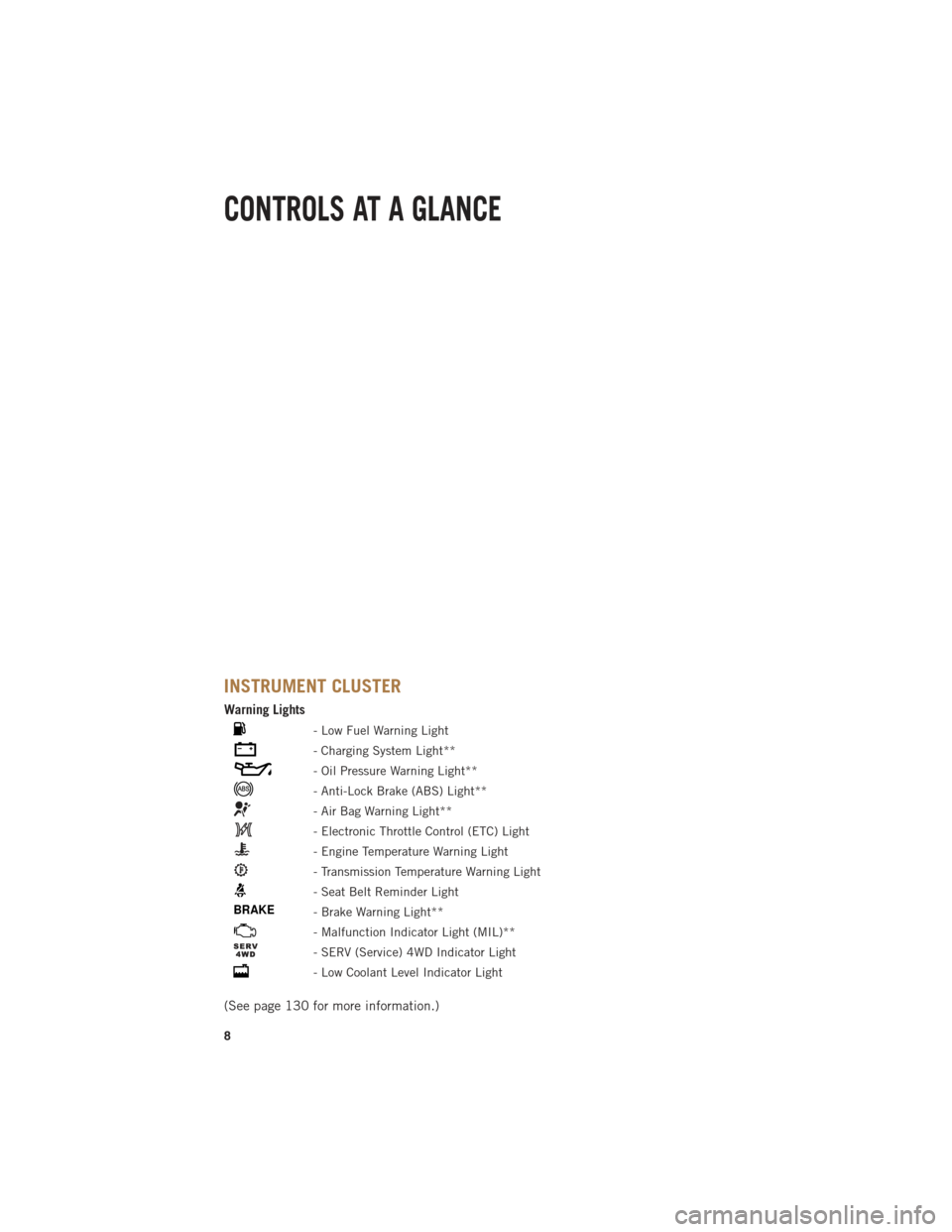

INSTRUMENT CLUSTER

Warning Lights

- Low Fuel Warning Light

- Charging System Light**

- Oil Pressure Warning Light**

- Anti-Lock Brake (ABS) Light**

- Air Bag Warning Light**

- Electronic Throttle Control (ETC) Light

- Engine Temperature Warning Light

- Transmission Temperature Warning Light

- Seat Belt Reminder Light

BRAKE- Brake Warning Light**

- Malfunction Indicator Light (MIL)**

- SERV (Service) 4WD Indicator Light

- Low Coolant Level Indicator Light

(See page 130 for more information.)

CONTROLS AT A GLANCE

8

Page 27 of 196

ENGINE BREAK-IN RECOMMENDATIONS

• A long break-in period is not required for the engine and drivetrain (transmissionand axle) in your vehicle.

• Drive moderately during the first 300 miles (500 km). After the initial 60 miles (100 km), speeds up to 50 or 55 mph (80 or 90 km/h) are desirable.

• While cruising, brief full-throttle acceleration within the limits of local traffic laws contributes to a good break-in. Wide-open throttle acceleration in low gear can be

detrimental and should be avoided.

• The engine oil installed in the engine at the factory is a high-quality energy conserving type lubricant. Oil changes should be consistent with anticipated

climate conditions under which vehicle operations will occur. For the recom-

mended viscosity and quality grades, refer to “Maintaining Your Vehicle”.

NOTE:

A new engine may consume some oil during its first few thousand miles (kilometers)

of operation. This should be considered a normal part of the break-in and not

interpreted as an indication to an engine problem or malfunction.

CAUTION!

Never use Non-Detergent Oil or Straight Mineral Oil in the engine or damage may

result.

DIESEL ENGINE BREAK-IN RECOMMENDATIONS

For diesel engine break-in recommendations, refer to Diesel Engine Break-In Recom-

mendations on pg.

120

OPERATING YOUR VEHICLE

25

Page 122 of 196

DIESEL ENGINE BREAK-IN RECOMMENDATIONS

• The Cummins®turbocharged diesel engine does not require a break-in period due

to its construction. Normal operation is allowed, providing the following recom-

mendations are followed: • Warm up the engine before placing it under load.

• Do not operate the engine at idle for prolonged periods.

• Use the appropriate transmission gear to prevent engine lugging.

• Observe vehicle oil pressure and temperature indicators.

• Check the coolant and oil levels frequently.

•

Vary throttle position at highway speeds when carrying or towing significant weight.

NOTE:

Light duty operation such as light trailer towing or no load operation will extend the

time before the engine is at full efficiency. Reduced fuel economy and power may be

seen at this time.

• Because of the construction of the Cummins

®turbocharged diesel engine, engine

run-in is enhanced by loaded operating conditions which allow the engine parts to

achieve final finish and fit during the first 6,000 miles (10 000 km).

DIESEL ENGINE STARTING PROCEDURES

Engine Block Heater

• For ambient temperatures below 0°F (-18°C), engine block heater usage is recommended.

• For ambient temperatures below –20°F (-29°C), engine block heater usage is required.

• The engine block heater cord is routed under the hood to the right side and can be located just behind the grille near the headlamp.

• Connect the heater cord to a ground-fault interrupter protected 110–115 volt AC electrical outlet with a grounded, three-wire extension cord.

NOTE:

The block heater will require 110 volts AC and 6.5 amps to activate the heater element.

•The block heater must be plugged in at least one hour to have an adequate warming

effect on the coolant.

Water In Fuel Message

•

If a Water In Fuel message orindicator appears in the cluster and a chime

sounds five times, the fuel/water separator will need to be drained immediately to

prevent engine damage.

• Refer to “Draining Fuel Water Separator” in this guide for draining instructions or see your dealer.

DIESEL

120

Page 123 of 196

Cold Start Procedure

• Turn the ignition switch to the ON position. If the Wait To Start

light appears

in the cluster, wait for the light to turn off before starting.

• In extremely cold weather below 0°F (-18°C) it may be beneficial to cycle the manifold heaters twice before attempting to start the engine. This can be

accomplished by turning the ignition OFF for at least five seconds and then back

ON after the “Wait To Start Light” has turned off, but before the engine is started.

However, excessive cycling of the manifold heaters will result in damage to the

heater elements or reduced battery voltage.

• Refer to the Owner's Manual Diesel Supplement on the DVD for further details.

Engine Idling

• Avoid prolonged engine idling. Long periods of idling may be harmful to your engine because combustion chamber temperatures can drop so low that the fuel

may not burn completely.

• Incomplete combustion allows carbon and varnish to form on piston rings, engine valves, and injector nozzles. Also, the unburned fuel can enter the crankcase,

diluting the oil and causing rapid wear to the engine.

• If the engine is allowed to idle, under some conditions the idle speed may increase to 900 RPM then return to normal idle speed. This is normal operation.

WARNING!

Remember to disconnect the cord before driving. Damage to the 110–115 volt

electrical cord could cause electrocution.

DIESEL EXHAUST BRAKE (ENGINE BRAKING)

• The exhaust brake feature will only function when the driver presses the exhaustbrake switch.

• The switch is located on the switch bank below the audio system.

• Your vehicle is also equipped with the Smart Brake feature.

• This feature will automatically provide a variable amount of engine braking in an attempt to maintain a constant vehicle speed.

• The Smart Brake is activated by pressing the exhaust brake switch twice. The first press activate the full strength brake, second press activates the Smart Brake and

third press turns the brake off.

• The Smart Brake target vehicle speed is set when either the vehicle brake or the throttle pedal is released.

• Exhaust braking is most effective when the engine RPM is higher.

NOTE:

For optimum braking power, it is recommended to use the exhaust brake while in

TOW/HAUL mode.

DIESEL

121

Page 125 of 196

ENGINE MOUNTED FUEL FILTER/WATER SEPARATOR

Draining Fuel/Water Separator

•

If the “Water in Fuel” indicator lightis illuminated and an audible chime is

heard five times, you should stop the engine and drain the water from the separator.

• The drain is located on the bottom of the Fuel Filter and Water Separator assembly which is located on the driver's side of the engine.

• Turn the drain valve (located on the side of the filter) counterclockwise 1/4 turn, then turn the ignition switch to the ON/RUN position to allow any accumulated

water to drain.

• When clean fuel is visible, close the drain and switch the ignition to OFF.

• Refer to the Owner's Manual on the DVD for further details.

Fuel Filter Replacement

• With the engine off and a drain pan under the fuel filter drain hose, open the water drain valve 1/4 turn counterclockwise and completely drain fuel and water into the

approved container.

• Close the water drain valve and remove the lid using a socket or strap wrench; rotate counterclockwise for removal. Remove the used o-ring and discard it.

• Remove the used filter cartridge from the housing and dispose of according to your local regulations.

• Wipe clean the sealing surfaces of the lid and housing and install the new o-ring into ring groove on the filter housing and lubricate with clean engine oil.

• Install a new filter in the housing. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter housing with fuel.

• Install the lid onto the housing and tighten to 22.5 ft lbs (30.5 N·m). Do not overtighten the lid.

• Start the engine and confirm no leaks are present.

The engine mounted filter housing is equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

1. No filter is installed.

2.

Inferior/Non-approved filter is used. Use of OEM filter is required to ensure vehicle

will run.

CAUTION!

•Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

•Do not prefill the fuel filter when installing a new fuel filter. There is a possibility

debris could be introduced into the fuel filter during this action. It is best to install

the filter dry and allow the in-tank lift pump to prime the fuel system.

•If the “Water In Fuel Indicator Light” remains on, DO NOT START the engine

before you drain water from the fuel filter to avoid engine damage.

DIESEL

123

Page 126 of 196

UNDERBODY MOUNTED FUEL FILTER/WATER SEPARATOR

Draining Fuel/Water Separator

•

If the “Water in Fuel” indicator lightis illuminated and an audible chime is

heard five times, you should stop the engine and drain the water from the separator.

• The drain is located on the bottom of the Fuel Filter and Water Separator assembly which is located in front of the rear axle above the drive shaft. The best access to

this water drain valve is from under the vehicle.

• Turn the drain valve (located on the side of the filter) counterclockwise 1 full turn, then turn the ignition switch to the ON/RUN position to allow any accumulated

water to drain.

• When clean fuel is visible, close the drain and switch the ignition to OFF.

• Refer to the Owner's Manual on the DVD for further details.

Underbody Fuel Filter Replacement

• With the engine off and a drain pan under the fuel filter drain hose, open the water drain valve 1 full turn counterclockwise and completely drain fuel and water into

the approved container.

• Close the water drain valve and remove the lid using a socket or strap wrench; rotate counterclockwise for removal. Remove the used o-ring and discard it.

• Remove the used filter cartridge from the housing and dispose of according to your local regulations.

• Wipe clean the sealing surfaces of the lid and housing and install the new o-ring into ring groove on the filter housing and lubricate with clean engine oil.

• Install a new filter in the housing. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter housing with fuel.

• Start the engine and confirm no leaks are present.

The underbody mounted filter housing will cause the engine not to run if:

1. No filter is installed.

NOTE:

• Using a fuel filter that does not meet the manufacturer's filtration and water separating requirements can severely impact fuel system life and reliability.

• The WIF sensor is re-usable. Service kit comes with new o-ring for filter canister and WIF sensor.

DIESEL

124

Page 133 of 196

•Your vehicle has also been equipped with a TPMS malfunction indicator to indicate

when the system is not operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the system detects a malfunction,

the telltale will flash for approximately one minute and then remain continuously

illuminated. This sequence will continue each time the vehicle is restarted as long as

the malfunction exists.

• When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure as intended. TPMS malfunctions may occur for a

variety of reasons, including the installation of replacement or alternate tires or

wheels on the vehicle that prevent the TPMS from functioning properly. Always

check the TPMS malfunction telltale after replacing one or more tires or wheels on

your vehicle, to ensure that the replacement or alternate tires and wheels allow the

TPMS to continue to function properly.

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air temperature

change. Keep this in mind when checking tire pressure inside a garage, especially in the

Winter. Example: If garage temperature is 68°F (20°C) and the outside temperature is

32°F (0°C), then the cold tire inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your

vehicle. Undesirable system operation or sensor damage may result when using

replacement equipment that is not of the same size, type, and/or style. Aftermarket

wheels can cause sensor damage. Do not use tire sealant from a can, or balance

beads if your vehicle is equipped with a TPMS, as damage to the sensors may result.

- Engine Temperature Warning Light

• This light warns of an overheated engine condition.

• If the light turns on and a warning chime sounds while driving, safely pull over and stop the vehicle. If the A/C system is on, turn it off. Also, shift the transmission into

NEUTRAL and idle the vehicle. If the temperature reading does not return to

normal, turn the engine off immediately.

• We recommend that you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

WARNING!

A hot engine cooling system is dangerous. You or others could be badly burned by

steam or boiling coolant. You may want to call an authorized dealer for service if

your vehicle overheats.

WHAT TO DO IN EMERGENCIES

131

Page 134 of 196

BRAKE- Brake Warning Light

• The Brake Warning light illuminates when there is either a system malfunction or the parking brake is applied. If the light is on and the parking brake is not applied,

it indicates a possible brake hydraulic malfunction, brake booster problem or an

Anti-Lock Brake System problem.

• Please have your vehicle serviced immediately.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system

may have failed. It will take longer to stop the vehicle. You could have a collision.

Have the vehicle checked immediately.

- Malfunction Indicator Light (MIL)

• Certain conditions, such as a loose or missing gas cap, poor fuel quality, etc., may illuminate the MIL after engine start. The vehicle should be serviced if the light

stays on through several typical driving cycles. In most situations, the vehicle will

drive normally and not require towing.

• If the MIL flashes when the engine is running, serious conditions may exist that could lead to immediate loss of power or severe catalytic converter damage. We

recommend you do not operate the vehicle. Have the vehicle serviced immediately.

- Electronic Stability Control (ESC) OFF Indicator Light

• If the ESC OFF indicator light comes on when the Electronic Stability Control (ESC) is off.

- Charging System Light

• This light shows the status of the electrical charging system. If the charging system light remains on, it means that the vehicle is experiencing a problem with

the charging system.

• We recommend you do not continue driving if the charging system light is on. Have the vehicle serviced immediately.

- Oil Pressure Warning Light

• This light indicates low engine oil pressure. If the light turns on while driving, stop the vehicle and shut off the engine as soon as possible. A chime will sound for four

minutes when this light turns on.

• We recommend you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

- Anti-Lock Brake (ABS) Light

• This light monitors the Anti-Lock Brake System (ABS).

• If the light is not on during starting, stays on, or turns on while driving, we recommend you drive to the nearest service center and have the vehicle serviced

immediately.

WHAT TO DO IN EMERGENCIES

132

Page 135 of 196

- Electronic Throttle Control (ETC) Light

•

This light informs you of a problem with the Electronic Throttle Control (ETC) system.

• If a problem is detected, the light will come on while the engine is running. Cycle the ignition when the vehicle has completely stopped and the shift lever is placed

in the PARK position; the light should turn off.

• If the light remains lit with the engine running, your vehicle will usually be drivable; however, see an authorized service center immediately. If the light is

flashing when the engine is running, immediate service is required and you may

experience reduced performance, an elevated/rough idle or engine stall and your

vehicle may require towing.

- Air Bag Warning Light

• If the light is not on during starting, stays on, or turns on while driving, have the vehicle serviced by an authorized service center immediately.

- SERV (Service) 4WD Indicator Light

• The SERV 4WD light monitors the electric shift four-wheel drive system. If the SERV 4WD light stays on or comes on during driving, it means that the four-wheel

drive system is not functioning properly and that service is required.

• For vehicles equipped with a premium cluster this indicator will display in the Electronic Vehicle Information Center (EVIC).

- Transmission Temperature Warning Light

• This light indicates that there is excessive transmission fluid temperature that might occur with severe usage such as trailer towing. If this light turns on, stop the

vehicle and run the engine at idle, with the transmission in NEUTRAL, until the

light turns off. Once the light turns off, you may continue to drive normally.

OIL CHANGE EVIC INDICATOR

Message

•If an “oil change” message (shown as "Change Oil Soon" and "Oil Change Needed")

appears and a single chime sounds, it is time for your next required oil change.

Resetting The Light After Servicing

• Turn the ignition switch to the ON/RUN position (do not start engine).

• Fully depress the accelerator pedal three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

- Low Coolant Level Indicator Light

• This light indicates low coolant level. If the light turns on while driving, stop the vehicle and shut off the engine as soon as possible.

• We recommend you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

133

Page 164 of 196

FLUIDS AND CAPACITIES

Gasoline Versions

Component Fluid, Lubricant, or Genuine Part Capacities

Engine Coolant

3.6L, 4.7L Engine We recommend you use MOPAR®

Antifreeze/Coolant 10 Year/

150,000 Mile Formula OAT

(Organic Additive Technology). 14 Quarts (13 Liters)

Engine Coolant

5.7L 1500 Models We recommend you use MOPAR

®

Antifreeze/Coolant 10 Year/

150,000 Mile Formula OAT

(Organic Additive Technology). 16 Quarts (15 Liters)

Engine Coolant

5.7L 2500/3500 Models We recommend you use MOPAR

®

Antifreeze/Coolant 10 Year/

150,000 Mile Formula OAT

(Organic Additive Technology) .18.7 Quarts (17.7 Liters)

Engine Coolant

5.7L 2500/3500

Models w/Heavy Duty We recommend you use MOPAR®

Antifreeze/Coolant 10 Year/

150,000 Mile Formula OAT

(Organic Additive Technology) .19.2 Quarts (18.2 Liters)

Engine Oil with Filter 3.6L, 4.7L, 5.7L We recommend you use

API certified 5W-20 engine oil, meeting the requirements ofChrysler Material Standard

MS-6395. Refer to you oil filler cap for correct SAE grade. 3.6L Engine - 6 Quarts

(5.7 Liters)

4.7L Engine - 6 Quarts (5.7 Liters)

5.7L Engine - 7 Quarts (6.6 Liters)

Engine Oil with Filter 5.7L

For 2500/3500 trucksoperating with a gross combined weight

rating greater than

14,000 lbs/(6,350 kg)

We recommend you use

API Certified SAE 5W-30 engine oil, meeting the requirements of Chrysler Material Standard

MS-6395. Refer to your engine oil filter cap for correct SAE grade. 5.7L Engine - 7 Quarts

(6.6 Liters)

Engine Oil Filter

3.6L, 4.7L, 5.7L We recommend you use MOPAR

®

Engine Oil Filters.

—

Spark Plug 3.6L We recommend you use MOPAR®

Spark Plugs. —

Spark Plug 4.7L We recommend you use MOPAR®

Spark Plugs. —

Spark Plug 5.7L We recommend you use MOPAR®

Spark Plugs. —

Automatic

Transmission —

Eight-Speed AutomaticWe recommend you use Mopar®

ZF 8&9 Speed ATF™ Automatic Transmission Fluid. —

MAINTAINING YOUR VEHICLE

162